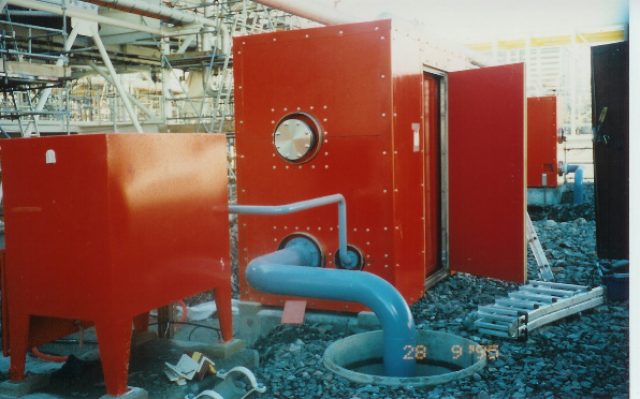

ProTek® Fire & Blast Enclosures

ProTek® Enclosures are certified by Det Norske Veritas (DNV) and are commonly used on offshore platforms and onshore petrochemical facilities where weight and space is always a constraint.

ProTek® Enclosures are manufactured using non-metallic lightweight composite products bolted to a secondary steel structure. They are designed and engineered to fit around critical equipment found in the oil and gas industry such as:

ESDV (Emergency Shut-Down Valve)

Actuators

Riser Hang-offs

A detailed survey ensures any nearby equipment or structure is accommodated which Solent Composite Systems use to deliver an engineered lightweight enclosure system that is rapid to assemble, permits inspection and maintenance access and avoids the use of hazardous materials or hot work during the installation. As it relies on mechanical fixings, no special skill or equipment are required.